| Building Type | Percentage of Steel Structures |

|---|---|

| Commercial buildings above five stories | 56% |

| New low-rise commercial buildings | 40% or more |

You choose steel structure buildings for many reasons:

- Steel supports heavy loads and spans wide spaces.

- It lasts for decades with little maintenance.

- Steel resists fire and pests.

- You can recycle steel, which helps the environment.

- Steel gives you design flexibility and saves money over time.

Steel is one of the most recycled materials worldwide, helping reduce waste and save energy. This makes your choice practical and eco-friendly.

Key Takeaways

- Steel structure buildings offer exceptional strength and durability, lasting 50 to 100 years with minimal maintenance.

- Fast construction is a key benefit; steel components arrive pre-engineered, allowing for quicker assembly compared to traditional methods.

- Cost savings are significant; steel buildings require less upkeep and often have lower initial material costs than wood or concrete.

- Design flexibility is a major advantage; steel allows for wide open spaces and customization to fit various needs and styles.

- Choosing steel supports sustainability; it is highly recyclable and reduces waste, making it an eco-friendly building option.

What is a steel structure building?

A steel structure building uses steel as its main load-bearing system. You see these buildings in places like factories, bridges, and commercial centers. Industry standards define a steel structure as a system made up of steel beams, columns, trusses, and girders. These components work together to support heavy loads and withstand harsh weather. You benefit from the high strength, durability, and flexibility that steel provides. This makes steel structure buildings a top choice for projects that need reliability and efficiency.

Core Features

When you look at a steel structure building, you notice several key components that set it apart:

- Primary Structural Framework: Steel columns, beams, and trusses form the backbone of the building. These parts carry the weight and keep the structure stable.

- Steel Columns: These vertical supports transfer loads from the roof and floors down to the foundation. They help the building resist wind and other forces.

- Steel Beams: Horizontal members support floors and roofs. They shape the layout and allow for open spaces inside.

- Steel Trusses: These lightweight elements span wide distances. You find them in buildings that need large, open areas like warehouses or sports arenas.

Tip: Steel structure buildings often use special materials for extra strength. You might see H-beams, T-beams, and structural steel channels in the framework. H-beams handle heavy loads, while C-channels and steel angles add support and reinforcement. Hollow structural sections provide strength in multiple directions, making the building even more stable.

You also find different types of steel in these buildings. Carbon steel offers high strength and weldability, making it common in construction. Stainless steel resists corrosion and needs little maintenance, which is useful in places where hygiene matters. Alloy steel brings extra toughness for demanding environments.

Steel vs. Other Buildings

You may wonder how steel structure buildings compare to those made from concrete or wood. The main difference lies in load-bearing capacity and strength. Steel stands out for its high strength-to-weight ratio and excellent tensile strength. Concrete works well under compression but needs reinforcement for tension. Wood has good tensile strength but cannot match steel or concrete for large structures.

| Material | Load-Bearing Capacity | Strength Characteristics |

|---|---|---|

| Steel | Superior | High strength-to-weight ratio, excellent tensile strength, ductility |

| Concrete | Good (in compression) | Requires reinforcement for tension, heavier foundations required |

| Wood | Limited | Good tensile strength but not suitable for large structures compared to steel and concrete |

Steel structure buildings give you more design flexibility. You can create wide, open spaces without many interior columns. Concrete buildings need thicker walls and heavier foundations. Wood buildings work for smaller projects but do not last as long or resist fire and pests as well as steel. When you choose a steel structure building, you get a strong, durable, and adaptable solution for many types of construction.

Benefits of steel structure building

Strength and Durability

You want a building that stands strong for decades. Steel structure building gives you that reliability. Steel resists pests, fire, and harsh weather. You do not have to worry about termites or rot. Steel buildings also handle earthquakes and severe storms better than wood or concrete. When you choose steel, you invest in a structure that lasts.

| Material Type | Average Lifespan |

|---|---|

| Steel Structure | 50-100 Years |

| Wood-Framed Building | 40-60 Years |

Steel buildings often last 50 to 100 years with minimal maintenance. Wood-framed buildings may need repairs or replacement much sooner. You save time and money because steel does not decay or warp. This durability makes steel structure building a smart choice for long-term projects.

Note: Steel’s strength allows you to build larger spaces without extra support walls. You get safety and stability for your investment.

Fast Construction

You want your project finished quickly. Steel structure building helps you meet tight deadlines. Most steel components arrive pre-engineered and ready to assemble. Workers can erect steel buildings in weeks for small projects. Larger facilities may take a few months, but steel construction is faster than traditional methods.

- Prefabricated steel systems speed up the building process.

- Smaller steel buildings, like garages, can be completed in weeks.

- Larger, customized structures may take several months, but planning keeps schedules on track.

- Steel construction is more efficient than wood or concrete.

Quick construction means you start using your building sooner. In business, this leads to faster operations and quicker returns on your investment.

Cost Savings

You want to keep costs low without sacrificing quality. Steel structure building offers cost-effective solutions. Prefabrication reduces labor expenses. Steel is often more affordable than wood or brick because of modern manufacturing. You also spend less on maintenance since steel resists damage and decay.

| Description | Cost Range |

|---|---|

| Metal building shell (framing & panels) | $25 – $40 per square foot |

| Complete metal building (including site prep, foundation, etc.) | $100 – $300 per square foot |

| Building kit alone | $8 – $50+ per square foot |

Steel buildings require less upkeep, which lowers long-term expenses. Proper insulation in steel structures can also reduce heating and cooling costs. You benefit from lower material costs, reduced labor, and minimal maintenance.

- Pre-engineered metal structures save on materials and labor.

- Steel buildings have lower annual maintenance costs.

- Energy-efficient designs help you save on utility bills.

Design Flexibility

You want a building that fits your needs and style. Steel structure building gives you design freedom. Steel’s strength lets you create wide, open spaces without many support walls. You can customize the look with different finishes and colors. Architects use steel to design innovative and attractive buildings.

- Steel structures allow for quick erection, minimizing time constraints.

- You can reuse or relocate steel buildings if your needs change.

- Aesthetic customization is possible, so you get the look you want.

- Steel supports larger open areas, perfect for warehouses, gyms, or showrooms.

Tip: Steel structure building adapts to your vision. You can expand or modify your building as your business grows.

Steel’s versatility means you do not have to compromise on function or appearance. You get a building that works for you now and in the future.

Types of steel structure buildings

Steel structure buildings come in many forms. You can choose a type that fits your needs, whether you want a large warehouse, a small garage, or a modern home. Leading US brands like Steel Buildings & Structures, Inc., Viking Steel Structures, LTH Steel Structures, VersaTube, Allied Steel, Worldwide Steel Buildings, and Armstrong Steel offer a wide range of options.

Industrial Buildings

You see steel used most in industrial settings. Common types include:

- Portal Frame Structures: These use vertical columns and horizontal beams. You get large open spaces without many interior supports.

- Beam and Column Frame Structures: These work well for multi-story factories and plants.

- Truss Structures: These use triangles for strength. You find them in warehouses and airplane hangars.

- Arch Structures: These create wide, open areas. You see them in storage and sports facilities.

- Grid Structures: These use steel bars connected at nodes. They spread loads evenly and allow for quick assembly.

Industrial steel buildings often house factories, distribution centers, and workshops. You can customize the size, doors, and insulation to fit your operation.

Commercial Buildings

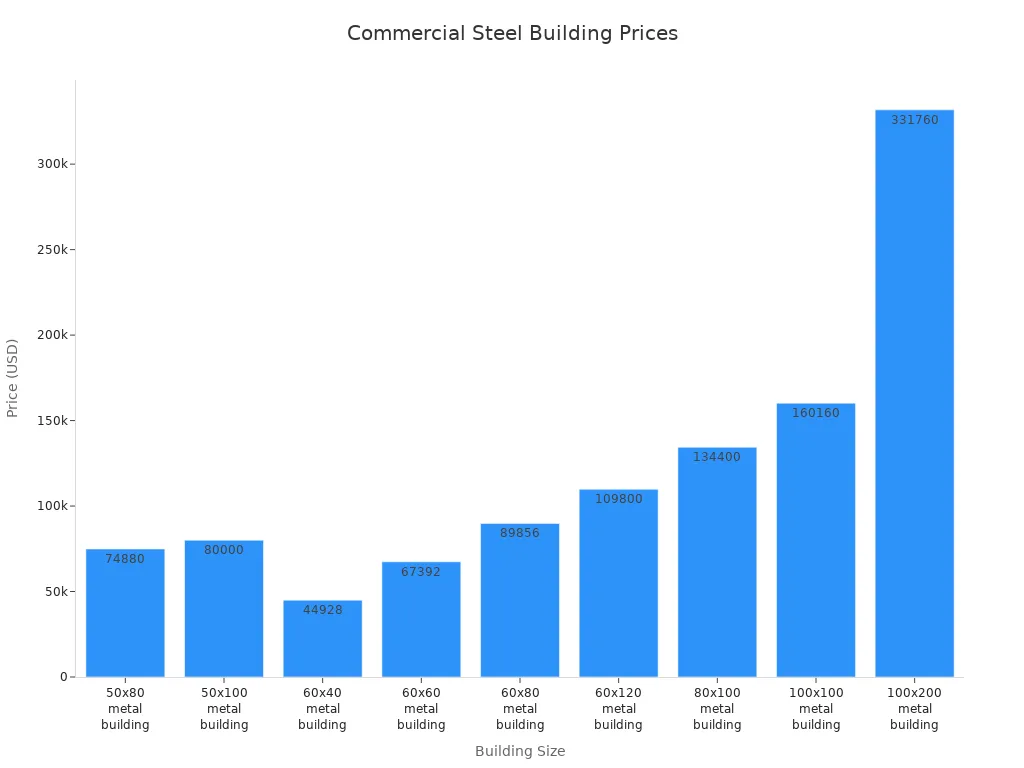

Steel works well for stores, offices, and showrooms. You can build car dealerships, retail centers, and even breweries with steel frames. Prices vary by size and design:

| Building Size | Price | Cost per sq. ft. |

|---|---|---|

| 50×80 | $74,880 | $18.72 |

| 60×120 | $109,800 | $15.25 |

| 100×200 | $331,760 | $16.59 |

Most commercial steel buildings cost $25 to $30 per square foot in 2025–2026. You can add features like glass storefronts, custom doors, and energy-efficient insulation.

Residential Buildings

You can use steel for homes, garages, barns, and even barndominiums. Many brands let you design your own space. Here is how top brands compare:

| Brand | Customization Options | Tools Available |

|---|---|---|

| Morton Buildings | Flexible design, color choices, architectural features | 3D visualization, color planners |

| Mueller | Custom dimensions, siding, roofing materials | 3D Estimator, Component Visualizer |

| Armstrong Steel | Tailored structures, wide range of options | Advanced design tools |

You can pick your layout, roof style, and finishes. Steel homes last longer and need less maintenance than wood.

Modular and Kit Buildings

You may want a quick, affordable solution. Modular and kit steel buildings arrive ready to assemble. Popular uses include:

- RV garages

- Farm buildings

- Shops

- Metal garages

- Auto repair shops

| Size | Popular Use |

|---|---|

| 24×30 | Auto Repair |

| 40×60 | Brewery |

| 100×100 | Agricultural |

| 200×400 | Basketball Court |

Pre-engineered steel kits make up over 60% of new low-rise commercial buildings. You can customize doors, windows, and colors. These kits save you time and money while giving you a strong, lasting structure.

Tip: You can always expand or modify your steel building as your needs change. Most brands offer easy add-on options.

Steel building construction process

Design and Planning

You start with careful design and planning. This phase sets the foundation for your steel structure building. Here is a typical process you follow:

- Decide if steel is the right choice for your project.

- Choose the best structural arrangement for your needs.

- Estimate the cross-sectional area for each part of the structure.

- Analyze the building’s stability and strength.

- Check all technical specifications to meet safety standards.

- Design the remaining parts, such as walls and roofs.

- Prepare detailed drawings for construction.

Tip: You should work with experienced engineers during this stage. They help you avoid costly mistakes and ensure your building meets local codes.

Fabrication and Delivery

Once you finish planning, you move to fabrication and delivery. This step transforms your design into real steel components. The process includes:

- Engineers create blueprints that follow building codes and load requirements.

- You select the right steel grades and thicknesses for your project.

- Machines cut steel parts with high precision.

- Workers bend and form steel into the required shapes.

- Welders join pieces together using advanced techniques.

- Inspectors check every part for quality and safety.

- Workers apply protective coatings to prevent rust.

- The finished steel components arrive at your site, ready for assembly.

Note: Quality control is essential. You want every piece to fit perfectly and last for years.

Assembly and Finishing

You assemble and finish your steel building on site. For a mid-sized commercial project, you can expect the following timeline:

| Phase | Duration |

|---|---|

| Frame Assembly | 1 to 2 weeks |

| Roof and Wall Installation | About 1 week |

| Installing Doors/Windows | 2 to 3 days |

| Interior Customization | A few days to several weeks |

You see fast progress during assembly. Workers use cranes and tools to lift and connect steel parts. After the frame stands, you add walls, roof panels, doors, and windows. You finish with interior work, such as insulation and painting. This process gives you a strong, reliable building in less time than traditional methods.

🚧 Quick assembly means you can start using your building sooner and reduce labor costs.

Key considerations for steel structure building

Cost and Budget

You need to plan your budget carefully before starting a steel structure building project. Many factors affect the final cost. Larger buildings require more materials and labor. Steel prices can change quickly, which impacts your budget. Complex designs and custom features add to expenses. Local building codes and climate may require special materials or reinforcements. Insulation and energy upgrades increase upfront costs but can save money over time. Foundation type, doors, windows, and delivery also play a role.

| Factor | Description |

|---|---|

| Building Size and Dimensions | Larger buildings require more materials and labor, increasing overall costs. |

| Steel Prices and Market Fluctuations | Variability in steel prices can significantly impact the budget, depending on market conditions. |

| Design Complexity and Customization | More complex designs necessitate additional materials and labor, raising costs. |

| Location and Building Codes | Local regulations and climate conditions can dictate material choices and structural reinforcements, affecting costs. |

| Insulation and Energy Efficiency Upgrades | Enhanced insulation and energy-efficient systems can increase initial costs but may save money long-term. |

| Foundation Requirements | The type of foundation needed can vary costs based on soil conditions and structural needs. |

| Doors, Windows, and Exterior Features | The choice and number of doors and windows can significantly influence the overall budget. |

| Delivery and Installation Costs | Transportation and labor for assembly can add to the final project costs, especially for larger structures. |

Tip: Compare suppliers and kits by looking at pricing, durability, insulation options, and customer support. Local suppliers may help you save on delivery and installation.

Maintenance Needs

Steel structure buildings need less maintenance than wood, brick, or concrete. You do not have to worry about pests, rot, or fire. Rust prevention and insulation management are important but less frequent. Protective coatings like galvanized finishes help prevent corrosion. Metal buildings usually cost less to maintain over time. Wood buildings need regular sealing, painting, and pest control. Brick and concrete may develop cracks or foundation problems.

- Steel buildings resist pests and fire.

- Rust and corrosion can be concerns in humid areas.

- Use protective coatings for long-lasting performance.

- Maintenance costs are lower compared to traditional buildings.

Environmental Impact

Steel is durable and recyclable. You help the environment by choosing steel, but steel production uses a lot of energy and releases carbon dioxide. Wood has a lower carbon footprint because it is renewable, but sustainability depends on how it is sourced. Concrete has a high environmental impact due to cement production. Many lumber companies use woody biomass for energy, making wood more sustainable.

- Steel is recyclable and lasts a long time.

- Steel production emits more carbon than wood.

- Concrete has the highest environmental impact.

- Wood produces less carbon, especially in tension-free structures.

Customization and Expansion

You can customize steel buildings to fit your needs. Many suppliers offer kits with flexible options. You choose the size, layout, insulation, and finishes. Leading brands provide strong warranties, often up to 50 years.

| Supplier | Warranty Duration | Description |

|---|---|---|

| Armstrong Steel | 50 years | Best in class structural warranty on all buildings. |

| Capital Steel | 50 years | Structural warranty coverage for every steel building. |

| General Steel | 50 years | Warranty where most companies offer only a one-year guarantee. |

| SteelMaster | 50 years | Warranty for eligible Quonset buildings, ensuring product reliability. |

You find DIY kits from brands like Rhino Steel Building Systems and AMF Steel Buildings. These kits include everything you need for assembly. Morton Buildings and Mueller Inc. focus on customer service and complete kits. When comparing suppliers, look at sizing, construction speed, durability, insulation, pricing, and support. Training and maintenance agreements add value, especially for DIY projects.

Steel structure buildings give you speed, safety, and value for money. You can choose from industrial, commercial, residential, or modular types.

“Prefabrication not only speeds up the construction process but also enhances quality control, reducing the risk and cost associated with on-site errors,” explains construction manager Daniel Rossi.

You benefit most from steel when you need design flexibility, durability, and sustainability.

- Prepare your site and foundation.

- Assemble the steel frame with care.

- Add insulation and finish the interior.

For quotes and customization, contact trusted suppliers:

| Supplier Name | Services Offered | Contact Information |

|---|---|---|

| Top Rank Steel Structures | Free quotes, customization, high-quality materials | (336) 790-5299 |

| Steel Buildings Solutionists | Complex designs, consultation, design services | Get a Quote |

| Armstrong Steel | Project guidance, quick quote form | Get Your Quote |

FAQ

What is the lifespan of a steel structure building?

You can expect a steel structure building to last 50 to 100 years. Steel resists pests, fire, and decay. Regular inspections and protective coatings help extend its lifespan.

Can you customize the design of a steel building?

You have many options for customization. You can choose the size, layout, colors, doors, and windows. Most suppliers offer design tools and flexible kits to match your needs.

How does steel compare to wood for building homes?

Steel offers greater strength and durability than wood. You do not worry about termites or rot. Steel buildings need less maintenance and last longer. Wood may cost less upfront but requires more repairs.

Are steel buildings energy efficient?

You can make steel buildings energy efficient by adding insulation and energy-saving windows. Proper design helps you reduce heating and cooling costs. Many suppliers offer eco-friendly upgrades.

Do steel buildings require special maintenance?

You need to check for rust and apply protective coatings when needed. Clean gutters and inspect insulation regularly. Steel buildings require less maintenance than wood or concrete structures.